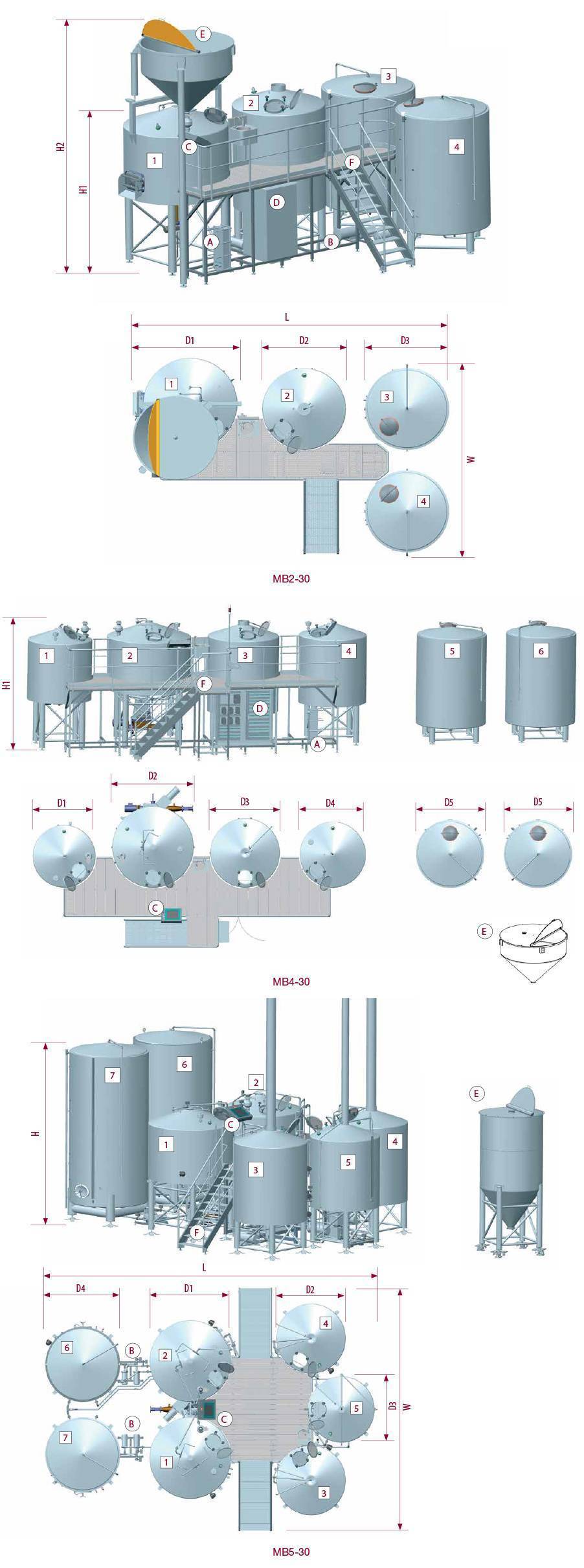

Microbrewery MB2 / MB4 / MB5

We plan and design complete medium-sized breweries. All systems can be designed with the client’s input for a defined process.

Design:

- A variety of different vessel combinations and a number of vessels: multifunctional tanks (mash mixer - lauter, kettle - whirlpool), individual process tanks (mash mixer, lauter, boil kettle, whirlpool, hot/cold water tanks)

- Fully piped and wired, including valves and sensors

- Staircases and platform combine the vessels in a compact unit, perforated and sectional construction of the walk-on surface ensures protection against slipping

- Integrated pump system

- Automated lautering, automated water mixing

Sanitary design:

- Polished internal tank surface and welds

- CIP system: separated CIP for individual tanks to prevent cross product interference

User friendly:

- All systems can be engineered with client input for defined process

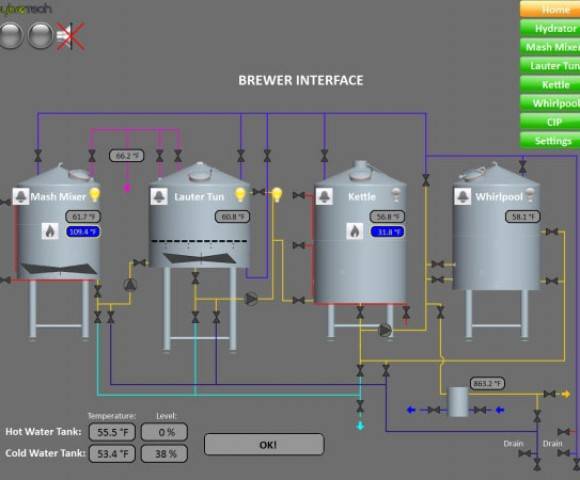

- Touch screen control panel

- Master brew interface control system (touch screen control panel)

- Possibility of manual control (pump on/off, temperature control, flow regulation)

Construction

| Main components | |||

|---|---|---|---|

| MB2-30 | MB4-30 | MB5-30 | |

| 1 | Mash mixer (MM) / Lauter tun (LT) | Mash mixer (MM) | Lauter tun (LT1) |

| 2 | Kettle (K) / Whirlpool (W) | Lauter tun (LT) | Lauter tun (LT2) |

| 3 | Hot water tank (HWT) | Kettle (K) | Kettle (K1) |

| 4 | Cold water tank (CWT) | Whirlpool (W) | Kettle (K2) |

| 5 | Hot water tank (HWT) | Whirlpool (W) | |

| 6 | Cold water tank (CWT) | Hot water tank (HWT) | |

| 7 | Cold water tank (CWT) | ||

| A | Heat exchanger | Heat exchanger | Heat exchanger |

| B | Pumps | Integrated pumps | Pumps |

| C | Control and operating panel | Control and operating touch screen panel | Touch screen control panel |

| D | Control cabinet | Control cabinet | Control cabinet |

| E | Grist case | Grist case (option) | Grist case |

| F | Platform with stairs and guardrails | Platform with stairs and guardrails | Platform with stairs and guardrails |

| MB2-30 | ||

|---|---|---|

| Mash mixer / Lauter volume (1) | L | 4820 |

| Kettle / Whirlpool volume (2) | L | 5810 |

| Hot water tank volume (3) | L | 7150 |

| Cold water tank volume (4) | L | 7150 |

| Tank diameter (D1) _ ID / OD | mm | 2135 / 2235 |

| Tank diameter (D2) | mm | 1983 |

| Tank diameter (D3) | mm | 2000 |

| Height without grist case (H1) | mm | 3550 |

| Height with grist case (H2) | mm | 5860 |

| Total length approx. (L) | mm | 7600 |

| Total width approx. (W) | mm | 4880 |

| MB4-30 | ||

|---|---|---|

| Mash mixer volume (1) | L | 3745 |

| Lauter tun volume (2) | L | 5800 |

| Kettle volume (3) | L | 5725 |

| Whirlpool volume (4) | L | 4780 |

| Hot water tank volume (5) | L | 7150 |

| Cold water tank volume (6) | L | 7150 |

| Mash mixer diameter (D1) | mm | 1850 |

| Lauter diameter (D2) _ ID / OD | mm | 2291 / 2387 |

| Kettle diameter (D3) | mm | 2035 |

| Whirlpool diameter (D4) | mm | 1935 |

| HWT/CWT diameter (D5) | mm | 2000 |

| Height without grist case (H1) | mm | 3580 |

| Height with grist case | mm | 6480 |

| Total length approx. (L) | mm | 9860 |

| Total width approx. (W) | mm | 6135 |

| MB5-30 | ||

|---|---|---|

| Lauter tun volume (1, 2) | L | 5800 |

| Kettle volume (3, 4) | L | 5725 |

| Whirlpool volume (5) | L | 4780 |

| Cold water tank volume (6) | L | 14350 |

| Hot water tank volume (7) | L | 14350 |

| Lauter diameter (D1) _ ID/OD | mm | 2291 / 2387 |

| Kettle diameter (D2) | mm | 2035 |

| Whirlpool diameter (D3) | mm | 1935 |

| HWT/CWT diameter (D4) | mm | 2200 |

| Total height approx. (H) | mm | 5090 |

| Total length approx. (L) | mm | 9765 |

| Total width approx. (W) | mm | 7140 |

gallery

Photos of the production

certificates

The quality of our equipment is documented:

- management and control, planning, production, sales and environmental management are regulated according to the ISO9001 and ISO14001 standards;

- requirements of our customers, general rules of the profession and good engineering and manufacturing practice are respected;

- TÜV certificate confirms compliance with the requirements of the EN ISO 3834-2 standard;

- conditions for the production of pressure vessels according to AD 2000 Merkblatt HP0 in HP 100 R, in combination with EN ISO 3834-2 are satisfied;

- planning and production of pressure vessels according to the Directive 97/23/EC (PED, Module H/H1) is supervised by the notified body for the conformity assessment (TÜV, CE 0531).