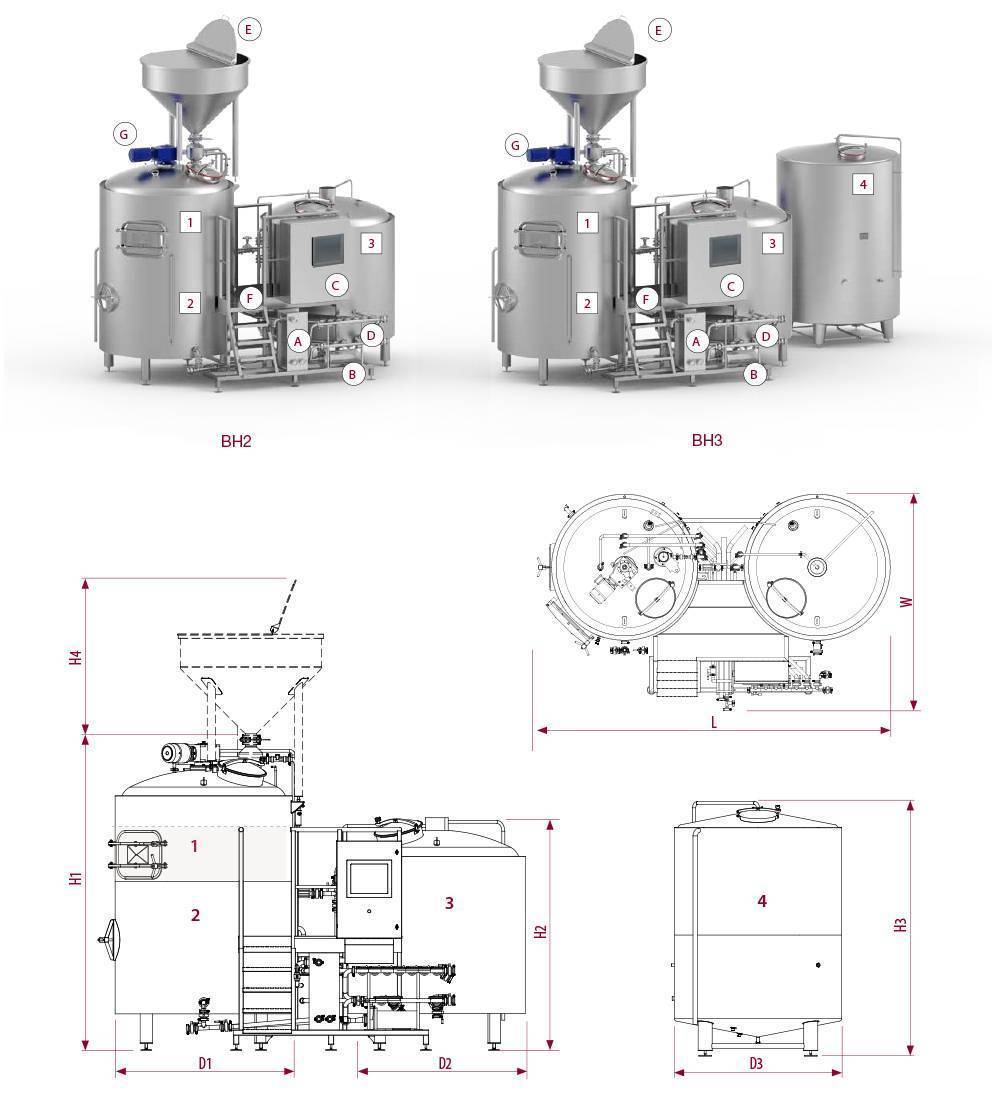

Compact Brewhouse BH2 / BH3

Single-temperature infusion mashing

Multi-step infusion mashing

Design:

- Combi tanks and multifunctional tanks in different combinations

- Completely wired and piped, including manifold with butterfly process valves

- Perforated false bottom

- Integrated pump (in the standard configuration the brewhouse is equipped with one pump; optionally the system can be upgraded with a second pump to improve the brewing capacity of the brewhouse

- Space saving design: support frame and perforated walk-on platform combine the vessels and other components in a compact block

Sanitary design:

- Polished internal tank surface and welds

- Easy and fast cleaning

User friendly:

- Master brew interface control system: temperature control, flow regulation, pump on/off, mixer rotation speed, setting of timers and step mashing parameters

- The system allows performing the multi-step mashing

- Available also in a configuration for high gravity brewing

Construction

| Compact Brewhouse BH2 | |

|---|---|

| 1 | Mash mixer (MM) / Lauter tun (LT) - upper comp. of combi tank |

| 2 | Hot water tank (HWT) - lower compartment of combi tank |

| 3 | Kettle (K) / Whirlpool (W) |

| A | Heat exchanger |

| B | Pump |

| C | Control cabinet with touch screen operating panel |

| D | Integrated process piping |

| E | Grist case (option) |

| F | Platform with stairs and guardrails |

| G | Rake plow with drive unit |

| Compact Brewhouse BH3 | |

|---|---|

| 1 | Mash mixer (MM) / Lauter tun (LT) - upper comp. of combi tank |

| 2 | Whirlpool (W) - lower compartment of combi tank |

| 3 | Kettle (K) |

| 4 | Hot water tank (HWT) |

| A | Heat exchanger |

| B | Pump (2x) |

| C | Control cabinet with touch screen operating panel |

| D | Integrated process piping |

| E | Grist case (option) |

| F | Platform with stairs and guardrails |

| G | Rake plow with drive unit |

| Brewhouse BH2 / BH3 | BH 10 hl | BH 20 hl | BH 25 hl | |

|---|---|---|---|---|

| Max. mash volume in tank (1) | L | 655 | 1580 | 1790 |

| Tank volume (2) | L | 1140 | 2800 | 2915 |

| Tank volume (3) | L | 1400 | 2670 | 3200 |

| Tank volume (4) | L | 2000 | 4100 | 5100 |

| Tank diameter (D1) | mm | 1335 | 1890 | 1990 |

| Tank diameter (D2) | mm | 1335 | 1760 | 1925 |

| Tank diameter (D3) | mm | 1370 | 1680 | 1680 |

| Tank height (H1) | mm | 2730 | 2790 | 2850 |

| Tank height (H2) | mm | 2050 | 2150 | 2210 |

| Tank height (H3) | mm | 2000 | 2500 | 3000 |

| Grist case height (H4) | mm | 1150 | 1610 | 1880 |

| Total length approx. (L) | mm | 3400 | 4250 | 4600 |

| Total width approx. (W) | mm | 1950 | 2510 | 2640 |

gallery

Photos of the production

certificates

The quality of our equipment is documented:

- management and control, planning, production, sales and environmental management are regulated according to the ISO9001 and ISO14001 standards;

- requirements of our customers, general rules of the profession and good engineering and manufacturing practice are respected;

- TÜV certificate confirms compliance with the requirements of the EN ISO 3834-2 standard;

- conditions for the production of pressure vessels according to AD 2000 Merkblatt HP0 in HP 100 R, in combination with EN ISO 3834-2 are satisfied;

- planning and production of pressure vessels according to the Directive 97/23/EC (PED, Module H/H1) is supervised by the notified body for the conformity assessment (TÜV, CE 0531).